Empowering One Of The World’s Largest Brewing Companies In Making Smarter Procurement Strategies Through Ai And Machine Learning Capabilities.

The Customer

The Customer Heineken N.V. is a Dutch brewing company, founded in 1864 in Amsterdam. Currently the world’s second-largest brewing company, Heineken owns over 167 breweries in more than 70 countries. It produces 250 international, regional, local and specialty beers and ciders and employs approximately 73,000 people. Through “Brewing a Better World”, sustainability is embedded in the business and delivers value for all stakeholders.

The Challenges

Heineken has made a public commitment to source 60% of its raw materials from the African region. The company was particular about the quality and the quantity of sorghum, barley and other ingredients required for its final product. They wanted to leverage technology to mitigate risks relating to raw material availability in their value chains and empower their local sourcing teams with a procurement toolkit so that they could better plan their purchasing targets. Season-wise mapping and monitoring of sorghum acreage at different stages held significance in sound marketing planning and inventory management for the client. The various teams carried out data collection and reporting using basic tools such as pen, paper, and spreadsheets. This excessive dependence on human labour resulted in more data loss and inconsistencies in acreage and yield estimations. Some of the specific challenges that the organisation faced include:

Manual Intervention in Crop Yield Estimation

• Labour intensive process

• Cost ineffective for large-scale estimation

• Inadequate monitoring due to lack of standard benchmarks

Data Quality Issues

• Labour intensive process

• Inaccurate reporting of yield at the plot level

• Poor data verification at different levels of management

Mismatch In Manual Data & Actual Yield

• Use of manual forms (area auditing, crop name, irrigation type, max yield value) by field team for capturing data

• Inconsistent yield and production forecast

• Intentional data manipulation

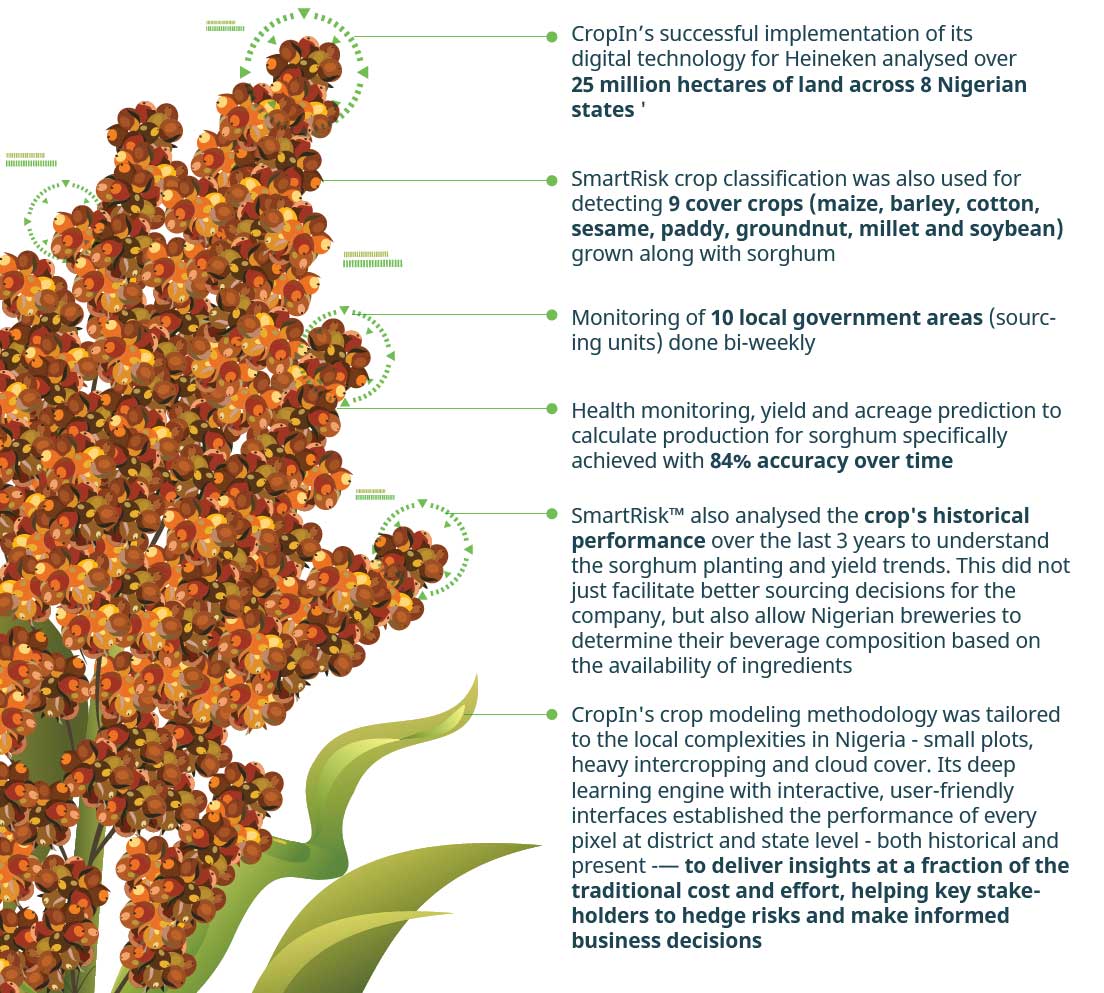

Results